Work on the Low-Carbon Roadmap for the Finnish Food and Drink Industry started in March 2020, and it was completed in August 2020.

The membership of the Finnish Food and Drink Industries’ Federation (ETL) was actively engaged during the project. From the start, the aim was to achieve

continuity for decarbonisation and the related roadmap work.

The current state of decarbonisation in the food industry

For now, there is no unified information source for the current state of decarbonisation in the food industry, which made it challenging to evaluate the sector’s decarbonisation. The evaluation of the current state in decarbonisation is largely based on interviews with food industry companies and an electronic survey of ETL member companies conducted in May 2020.

Food industry operations typically generate little if any direct greenhouse gas emissions. What little direct emissions there are from production processes are typically related to the use or generation of carbon dioxide (e.g. stunning, smoking, roasting, and fermenting). Direct emissions are also generated by the plants’ internal or adjacent energy production. For most companies, the direct greenhouse gas emissions of food production amount to between zero and 30 per cent of the product’s life cycle emissions. The majority, 60 to 80 per cent, are related to situations where the company produces its own energy. Self-sufficiency in terms of energy production is rare in the industry, and purchased energy is often used.

Companies in the industry have carried out energy efficiency measures to reduce direct emissions, such as developing heat recovery and reducing energy consumption. In addition, many companies have adopted low-carbon energy production methods, with biosteam plants and biogas use on the

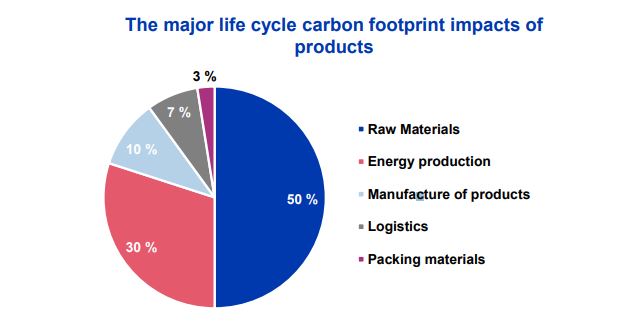

rise in particular. The operations of food industry companies generate much more indirect than direct greenhouse gas emissions. The majority of a food product’s life cycle greenhouse gas emissions are generated during primary production or energy production (Image 1). To a lesser extent, indirect emissions are generated by logistics and packaging materials. Additional greenhouse gas emissions are generated in different parts of the value chain, including consumer food waste.

Image 1. The major life cycle carbon footprint impacts of products are the result of raw material manufacturing

(sources: Finnish Food and Drink Industries’ Federation)

The roadmap suggests that Finland’s national legislation, financing and incentive systems, and high level of technology have resulted in large-scale adoption of the best available technology (according to the BAT conclusions of the Industrial Emissions Directive) among food industry companies. In Finland, responsibility and climate change mitigation have been recognised as a competitive advantage in time, which is why large companies in particular are already widely implementing emission mitigation techniques. Statutory conformity requirements have also ensured that small and medium-sized enterprises have a good level of readiness for emission reductions in general.

Energy and materials efficiency solutions are in widespread use in Finland, especially in large food industry companies. This is due to government-subsidised systems (including energy performance contracting) and direct government influence on energy use costs in companies.

Objective and goal state conditions

The vision of the food industry low-carbon roadmap for 2035 is that low-carbon solutions will have been widely adopted in the sector, and that climatic effects will be well-managed in the food industry value chain. The Finnish Food and Drink Industries’ Federation is aiming for carbon neutrality in cooperation with companies in the industry. The 2035 target of the industry is to reduce the sector’s greenhouse gas emissions by 75 per cent relative to net sales. The food industry is firmly committed to advancing the entire food supply chain’s efforts to reach carbon

neutrality.

A predictable and stable operating environment is essential for promoting decarbonisation in companies. The industry states that the government must support low-carbon operating methods in a predictable manner between 2020 and 2035. In this, the different starting points of companies and the opportunities and obstacles posed by the food industry’s diversity should be taken into consideration. In particular, the restrictions and special features brought on by food industry regulations must be noted when assessing food industry operations.

Main solutions for achieving the objective

As a whole, the food industry generates relatively few direct emissions, which is a good starting point for a low-carbon future. The roadmap lists a number of measures for realising the low-carbon vision and goal state, included in Figure 18. The essential measures are related to predictable government measures to support low-carbon operating methods and theavailability and adoption of low-emission energy. Shared and harmonised, LCA-based calculation methods will also need to be developed based on scientific facts. One suggested measure is the continuation and deepening of the roadmap work.

Image 2. Primary means identified by companies for reducing the operational carbon footprint

(sources: Finnish Food and Drink Industries’ Federation)

Energy production is one of the most significant emission sources in the life cycle of food products. According to the roadmap, the transition to alternative fuels and zero-emission energy will require government direction and initiative from the companies themselves.

The emissions of energy production can also be reduced by increasing the share of renewable energy and by accelerating energy efficiency measures considerably across all member companies of the Finnish Food and Drink Industries’ Federation regardless of size. This requires

investments in energy-efficient systems, energy audits, and the sharing of best practices and information. Pioneering companies have a major influence on the building of the food industry knowledge base and toolkit for decarbonisation.

Most companies in the industry estimate that a further reduction of 10 to 30 per cent in energy consumption can be achieved with energy efficiency measures. Furthermore, many food industry companies consider it possible to replace most or all energy used with renewable, low-carbon

energy at some point in the future.

Solutions related to the utilisation of production side streams and the prevention of production losses should be adopted more widely, as there exists a lot of unused potential.

The calculation of greenhouse gas emissions and product carbon footprint calculation are core elements in transitioning to low-carbon business. This requires harmonised scientific and LCAbased calculation methods, as well as emission factors that take into account the nutritional value of the food products. The calculation methods must be compatible at national and international levels. This will ensure that the product emissions are comparable and that they remain

competitive on the international market.

In the case of food, the majority of emissions are generated during primary production, which is outside the scope of the food industry’s roadmap. This is why cooperation in the value chain is of paramount importance for decarbonisation. Existing cooperation must be strengthened, particularly between primary production and the food industry, to reduce greenhouse gas emissions and harmonise the calculation of emissions from raw materials. To this end, open information sharing will be necessary, along with identifying the impacts of the different operators in the value chain.

More information

Study on the significance of biodiversity for the Finnish food industry

Here you find information about the biodiversity study briefly (pdf)

Read here